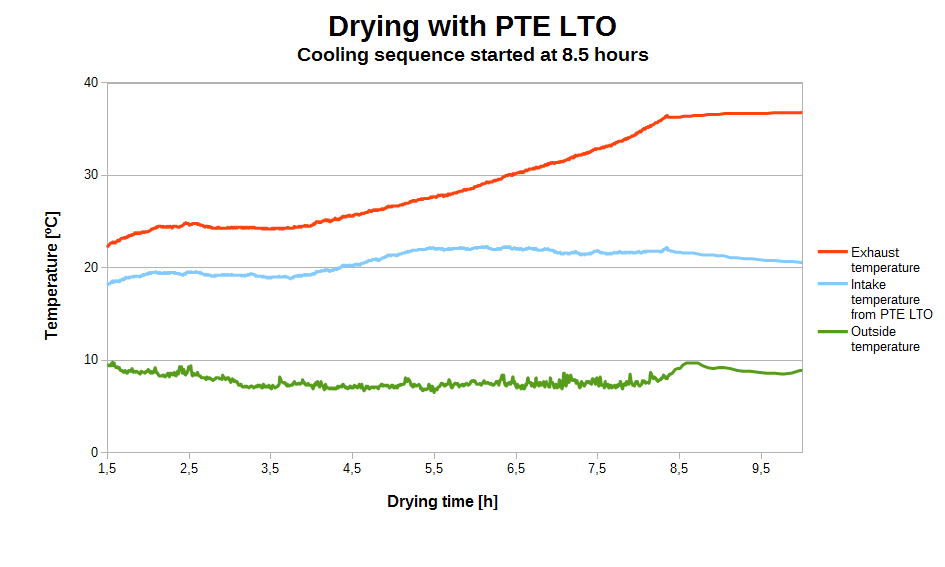

The first prototype was installed in 2010 to wagon grain dryer manufactured in 70’s . The results were amazing. In theory, PTE-LTO decreases the oil consumption about 30%. In practice, however, an old wagon grain dryers oil consumption with PTE-LTO was over 50% less than with the next-operating almost new wagon grain dryer without heat recovery. Because of the increased efficiency in drying, very wet grain is now economically viable.

Heat recovery unit consists of temperature gauges, control valve, piping, filtration unit and effective heat exchanger. Exhaust air heat energy is recovered efficiently and used to preheat the intake air. Despite the dusty and damp conditions, we have managed to build filtering that actually works.

Typically, the filter exchange is not required during the drying season.

Heat recovery unit can be installed to almost all existing (retrofit) and new (new installation) warm-air dryers.

contact us